The revolutionary EDM tapping accessory!

The EDtapper adds CNC capabilities to your sinker EDM machine, allowing you to tap a wide variety of holes. Just attach to machine as you would an electrode with magnet or shank, affix electrode to electrode holder, position appropriately, extend and fix base foot, adjust horizontal movement scale, set the depth of sinking to 42mm and operate. Complete setup takes just 5 minutes!

The EDTapper

Cat. # 603446 100015

EDTapper millimetric version in wooden box.

Contents:

boss attachment, 42mm gage, key and holder for flat profiled electrodes.

Cat. # 603446 100022

EDTapper inch version in wooden box.

Contents:

boss attachment, 1.65″ gage, key and holder for flat profiled electrodes.

Additional Products in box:

Cat # 603446 100039

Flat electrode holder. Electrode-to-Shaft attachment.

Cat # 603446 100053

Key

Cat # 603446 100046

42mm (1.65") gage

Cat # 603446 100107

Collet with rubber adaptor (not included)

Features & Benefits

- CNC capabilities on sinker EDM. (Fig.1)

- Converts the Z-axis vertical movement to an orbital movement.

- The EDtapper forms the whole depth of the thread in a single orbital cycle.

- No need for interfering with the machine's electronic circuits – attach as an electrode holder and it’s ready to operate.

- 5-minute setup only!

- The EDtapper is controlled via the familiar control panel of the machine.

- Maintains the EDM machine features of sinking and withdrawal.

- Withdrawal of electrode designed so it is always towards the center of the hole and not in the direction from which it came in order to achieve improved flushing.

- Up to 3.2 mm (1/8") horizontal movement in 0.02 mm (0.001") increments.

- Special flexible hose for spraying fluid directly through the electrode for blind threads.(Fig.2)

- Two positions for attachment of electrode:

- A special electrode attachment enables the removal and replacement of the electrode without losing pre-settings for threads (to prevent cross-threading).

Applications

Technical Info

Some results of the EDtapper performances:

Copper electrode on hardened steel

M5 thread to depth of 8 mm takes 12 minutes (roughness 5.2 Ra)

M10 thread to depth of 16 mm takes 18 minutes (roughness 6 Ra)

M12 thread to depth of 20 mm made by 2 steps:

Coarse: 25 minutes (roughness 6.8 Ra) – and then

Fine: 6 minutes (roughness 4.8 Ra)

Similar results in accordance for:

NF10-32 to depth of 0.3”

NC3/8 to depth of 0.625”

NC1/2 to depth of .75”

Copper electrode on carbide end mill.

M6 x 1 male thread* (similar to NF1/4) on 6 mm shank made in 2 steps:

- coarse takes 50 minutes but the thread profile was not full due to electrode tips wear.

- fine takes 40 minutes (roughness 2.24 Ra) .

As it can be seen work duration is much longer than on steel and electrode wear also higher.

Modern machines have exact adjustable conditions for carbide etching.

1

Attach to machine as you would attach an electrode holder using magnet.

1-2

Or attach with shank and then align on the upper plate

2

Attach electrode to electrode-holder.

3

Position. (center & depth)

4

Extend and fix base foot to convert vertical to orbital mode.

5

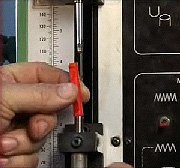

set the depth control so that the machine head can descend 1.65" (42mm)

6

Adjust horizontal movement scale.

7

OPERATE!

Specifications

| Specifications: | Inch: | Metric: |

|---|---|---|

| Weight: | 3.8 lbs. | 1.7 kg |

| Force resisting head movement: | 17.6 lbs. | 8 kg |

| Max. Electrode Wt. | 2.2 lbs. | 1 kg |

| Completion of orbital turn: | 1.65” on Z-axis (1.57” + 0.08” overlapping) | 42 mm on Z-axis (40 mm + 2 mm overlapping) |

| Radial Feed Movement | 0.125" | 3.2mm |

| Maximum thread pitch that can be formed | 5 T.P.I. or 5 mm | 5 mm or 5 T.P.I. |

| Feed Scale Division | 0.001" | 0.02mm |

| Foot Stroke | 2.15" | 55mm |

| Diameter of electrode rod for mounting in holder: | Ø1/8" – Ø13/16" (0.125"-0.812") | Ø3 mm - Ø20 mm |

| Maximum electrode diameter: | 6" | Ø150 mm |

| Accuracy of tapping location in regard to hole: | ±0.0035" | ±0.09 mm |

FAQ

Yes. You can make it either by drilling or by EDM sinking.

The same as for cutting regular thread – just use the standard tables.

Yes. It should be that way. The electrode pitch must be the same as the thread you need but its outer diameter should be smaller than the pilot hole. For example: the recommended diameter of an electrode for making M8 thread is 6.2 – 6.3 mm. The diameter of an electrode for NC3/8 is 0.29″ – 0.3″

The tool is making threads using the ORBITAL method – you have to penetrate with the electrode to the desired depth and then the EDtapper makes all the windings in a single orbital turn. It should not turn about itself since it copies the electrode helix shape to the interior walls of the hole.

No. The pitch is set solely by the electrode. The pitch of the thread will be identical to that of the electrode.

The scale determines the orbital movement radius. When the scale is closed all the way the electrode does not move out of place. Only in this state should the positioning of the electrode – in the pilot hole center – be made. When the scale is opened, the electrode is able to move out of the center to the value appearing on the scale, and orbital movement will take place at this radius.

The accessory must be connected to the machine in a position PARALLEL to the Z-axis (the sinking axis). If the connection point is not rigid (i.e. can be adjusted by means of alignment screws) it must be aligned, using a gauge on the PLATE FOR ATTACHMENT TO MAGNET (2).

Yes. Up to 2 mm of exact horizontal movement (see para. 2-2.2 , page 18 on the manual) and up to 3.2 mm for not accurate purposes.

No, this won’t damage the machine since the accessory is telescopicand can be contracted. When the machine head descends it senses only the resistance of an internal spring, up to 8 kg (17.6lb). Of course, care must be taken not to allow the head to descend more than 42 mm after the base foot touches the table.

The EDtapper is marketed in two versions: metric or inches. You can use the inch version EDtapper for making both inch and metric threads (and so with the metric version); it depends on the electrode being used. The difference is the scale – when you use an 8mm diameter electrode for making M10 thread you have to turn the scale 1 turn (i.e. 1mm) on the metric version. On the inch version you have to set the scale to 39 (i.e. 39 thousandths of an inch or 0.039″) which is actually 1mm.

The choice of which version to use depends on convenience to the user.

The instruction manuals are the same, but all the units of measure are different – the dimensions, the examples, the figures of the scale, the equations, etc.

An electrode can be attached to this shaft using the supplied Electrode-to-Shaft attachment. Attachment to this point will cause the electrode to move from the center in accordance with the adjustment of the scale and also to rotate about itself. A flat profiled electrode can burn cavities having circular symmetry. Refer to chapter 2-2.3 on the manual (page 19)

It helps to set the descending of the machine head to 42mm or 1.65″ after the electrode is at the needed depth and the base foot touches the table. It is for those having machines with dial gage. While the machine head descending 42mm the EDtapper finished full orbital cycle.

Downloads

Trouble Shooting

• The base foot wasn’t pulled down.

• The base foot wasn’t fixed well.

See page 10 step H on the manual

• The scale wasn’t set, but rather left tightened and no horizontal movement occurred. Refer to page 12 stage J and set the scale.

See page 12 step H on the manual

• Check first whether the thread is indeed not concentric – see below or, the case is that the process stopped in the middle – refer to 4.

• The centering process was made with scale screw not tightened – refer to page 10 F.

See page 10 step H on the manual

• The machine table moved after centering.

• The whole tool is not attached firmly.

• The process stopped in the middle because the setting of the head descending was not done properly. Allow the head to descend 42mm (1.65”) after the base foot touches the table.

• The head reached its limit before ending the 42mm (1.65”).

• The scale screw is not tightened.

• The whole tool is not attached firmly.

• The work-piece is not fixed.

• The scale wasn’t opened enough. Open the scale some more.

• The electrode is worn, or the machine conditions caused fast electrode wear-out, especially at the tips. Open the scale some more or replace an electrode. See notes of replacing electrode during process.

See notes of replacing electrode during process – manual page 16 para. 2-2.1

• The electrode pitch is wrong – choose the right one. see …

About Us

Shilo Technologies Ltd. was founded in 1986 to provide multipurpose, cost-effective, innovative mechanical and electro- mechanical tools for the professional and Do-It-Yourself user. Our tools feature a unique approach to thread repair in a line of high-quality tools oriented towards ease and simplicity of operation. The company is located in Israel, and markets worldwide.

Shilo Technologies Ltd. is a leading manufacturer of innovative hand tools focusing on the field of thread restoring. Its first product, the “Nes 1 External Thread-Restoring Tool” is a revolutionary hand tool, used by professionals and maintenance personnel, as well as high level Do-It-Yourself users, to restore damaged threads.

Due to the innovative nature of the cost-effective products, the user can correct a wide range of thread types on site. Following positive reporting by some very prestigious publications – including “Popular Mechanics” – Shilo moved forward, expanding its product range with the Nes 2 and Nes 3 . The next stage debuted in the year 2000 – a full range of internal threads repairing tools.

Shilo is now introducing a new range of tools for repairing small internal threads that will further enhance the product range and position the company at the forefront of thread restoring technology.

The new and innovative EDTapper is extending the company activity into a new area – the machining of hard metals using the EDM process – while still remaining in its main area of expertise – threading.

Shilo Technologies Ltd. participates regularly in the major international tool exhibitions, demonstrating its product family. The products are protected by patents and Intellectual Property Rights.

World-wide sales – in the USA, Europe and the Far East – are conducted via a network of international distribution outlets. Among Shilo’s customers are some leading companies in a wide range of industries.

Contact Us

All rights reserved: 2008 © SHILO Technologies ltd.

Site by: Visuali